Delivering the news with neither incredulity nor hype, Lining Yao is readying her audience for what is to take place onscreen. Something intimate – a coming together of science and fashion.

“The notion of an actuator can go beyond man-made systems and enter the biological kingdom,” declares Yao, via video recording.

Yao and her MIT Media Lab team are the proud creators of a new "bio-skin", a fabric that peels back in reaction to a wearer’s sweat and humidity in the air.

From the MIT university lab in Massachusetts, millions of the bacteria ‘natto’ cells have been grown and cultivated for use in a micron-resolution bio-printer.

“These animate cells are harvested in a bio lab, assembled by a micron-resolution bio-printing system, and transformed into responsive fashion,” explains Yao.

The printed film composites were then given to designers at the Royal College of Art in London, who integrated them into clothing. Forming heat ‘maps’, the cells line the areas of the body where humans sweat the most during physical exertion.

The cultivated bacteria was first discovered 1,000 years ago by a Japanese samurai. A Bacillus Subtilis strain, the ancient bacteria is used to ferment foods in Japan, including natto – a soybean-based dish. Now it’s the basis of the cutting-edge sports fabric, thanks to BioLogic – the collective name behind the scientists and innovators who’ve created this new wonder fabric.

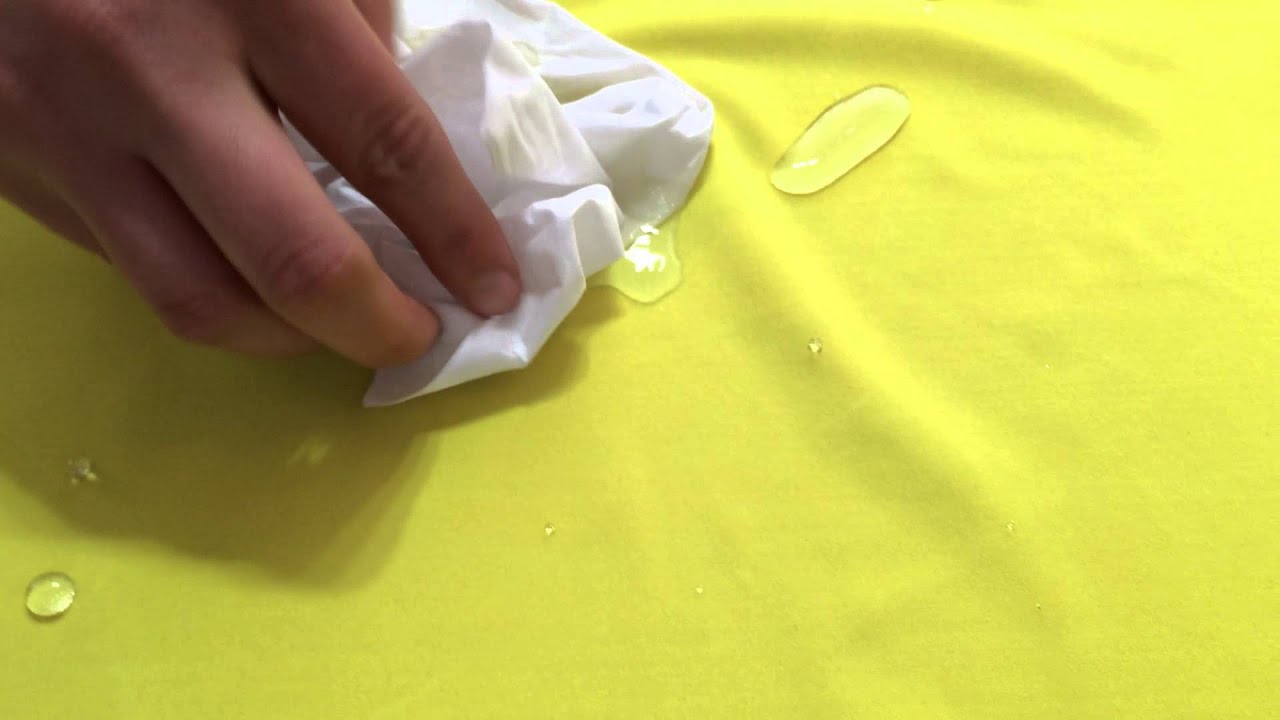

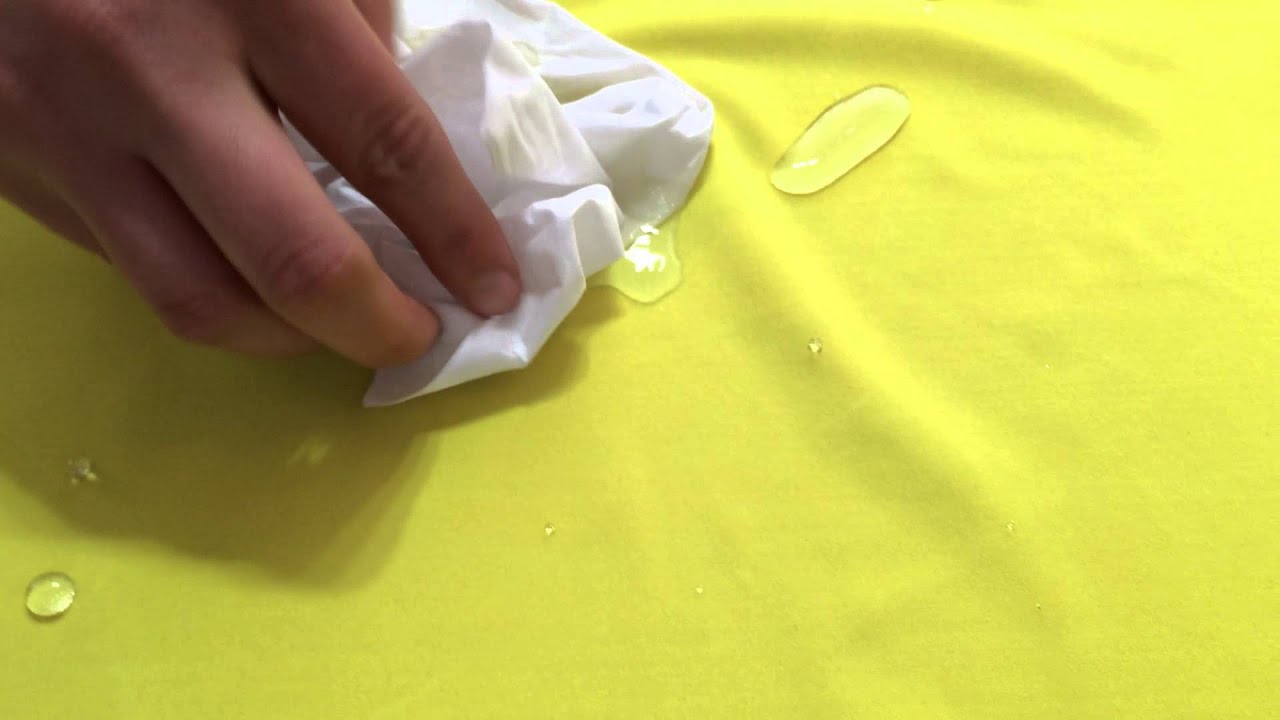

The synthetic bio-skin reacts to body heat and sweat causing flaps around heat zones to open, enabling sweat to evaporate and cool down the body through an organic material ‘flux’.

So how does the fabric look in action? The BioLogic team dressed two dancers in skin-tight body suits made from the bio-fabric. The triangle-pointed openings, covered in two flaps, mark out the ‘map’ areas where the bacterium has been fed to the fabric after cultivation.

Then, the flaps peel back, as the wearer starts to warm up. It’s this waving motion that provides much needed ventilation and helps the dancers cool down – during and after the choreographed moves. This allows the wearer to feel strong in their activity and outfit.

It’s all about peak performance, believes Daniel Chalem, president of Colombia-based active textile firm Tejidos Gulfer.

Located in the thriving Bogota, Tejidos Gulfer specializes in performance fabrics. It’s the Colombian leader in tricot, rachel and circular knits, used primarily in sportswear, shapewear and swimwear. What

keeps the mill ahead of the pack? Constant innovation.

Tejidos started making textiles following the end of the Second World War. And, nearly 50 years on, the firm is a vertically integrated powerhouse with a huge emphasis on innovation. All aspects of production– from spinning to finishing – are done in-house.

“We have our own spinning operation, so we get the yarns in big cakes and spin them ourselves into smaller manageable amounts that go into the various machines,” Chalem explains.

According to Chalem, the mill uses a combination of specialty yarns and finishings in their specialized finishing plant. These can vary from in-yarn moisture management to antibacterial agents to odor repellent.

“Fabric has a big impact on a wearer’s performance. The fabric is designed to provide comfort and performance, and let the wearer concentrate on their activity,” Chalem adds.

“For example, a fabric that has moisture management absorbs the sweat so the user is not sticky. Cold fabrics give the user comfort in hot or high intensity training.”

Textile innovation has become a focus area for many mills. Consumers expect more from their clothes. Users want stain-free, sweat-free, odor-free apparel and it must be fashionable. It’s why athleisure – the term used to describe the mixing of active wear and casual fashion – has become such a huge movement.

“The market has changed a lot,” explains Chalem. “Now users not only demand more - since the exercise is more intensive - but also they wear the garments throughout the day.”

The market’s need for functional and fashionable clothing has blurred the lines between say, gym clothes, and casual wear. It’s now acceptable for women to wear leggings to a bar or out

to Sunday brunch (over a pair of luxury sneakers usually) and nobody bats a mascara-clad eyelid for doing so.

Meanwhile, brands like Stella McCartney and Tory Burch have caught wind of the craze and capitalized with designer active-fashion collections catering to the most luxury tastes.

As the pace for faster, better, stronger apparel quickens, getting the garments to the wearer - even quicker - is the next step. Consumers want even more high-performing fashion, be it authentic gym-goers or feigning fashionistas. But translating the incredible science that goes into an active shirt or a pair of leggings is an issue: How can shoppers know what technology it is that they are buying into?

Back in Massachusetts, the BioLogic crew have pre-empted this problem. Their ‘Second Skin’ material is already confirmed to be used in the collections of New Balance – one of the activewear segment’s hottest brands.

The question still remains: Does such specialized performance technology have the stamina to last?

“I’m not sure,” says Chalem. “It will depend on several factors including costs, comfort and relativity.”

It’s certainly not a sure-fire necessity for users who want the active look but aren’t really breaking into a sweat.

New garments tend to take-off from the starting block as the season’s ‘it’ performance pieces, but only the fittest – and most fashionable – win. It’s all about longevity that highlights success, says Chalem.

“I’ve seen a lot of things come and go.”