June 17th, 2024 - ELLEN MACARTHUR FOUNDATION

A comprehensive circular economy approach is the only solution that can match the scale of the global textile waste problem. Extended Producer Responsibility (EPR) policy is a necessary part of the solution. Our report explores a common approach across national EPR systems, to maximise alignment and effectiveness, as well as the many benefits EPR can bring, beyond downstream waste management.

What is EPR and Why Do We Need it?

To establish separate textile collection systems at scale, dedicated, ongoing and sufficient funding is needed to cover the net cost associated with managing all discarded textiles, not just the fraction with high reuse value. EPR is a crucial policy mechanism to deliver such funding.

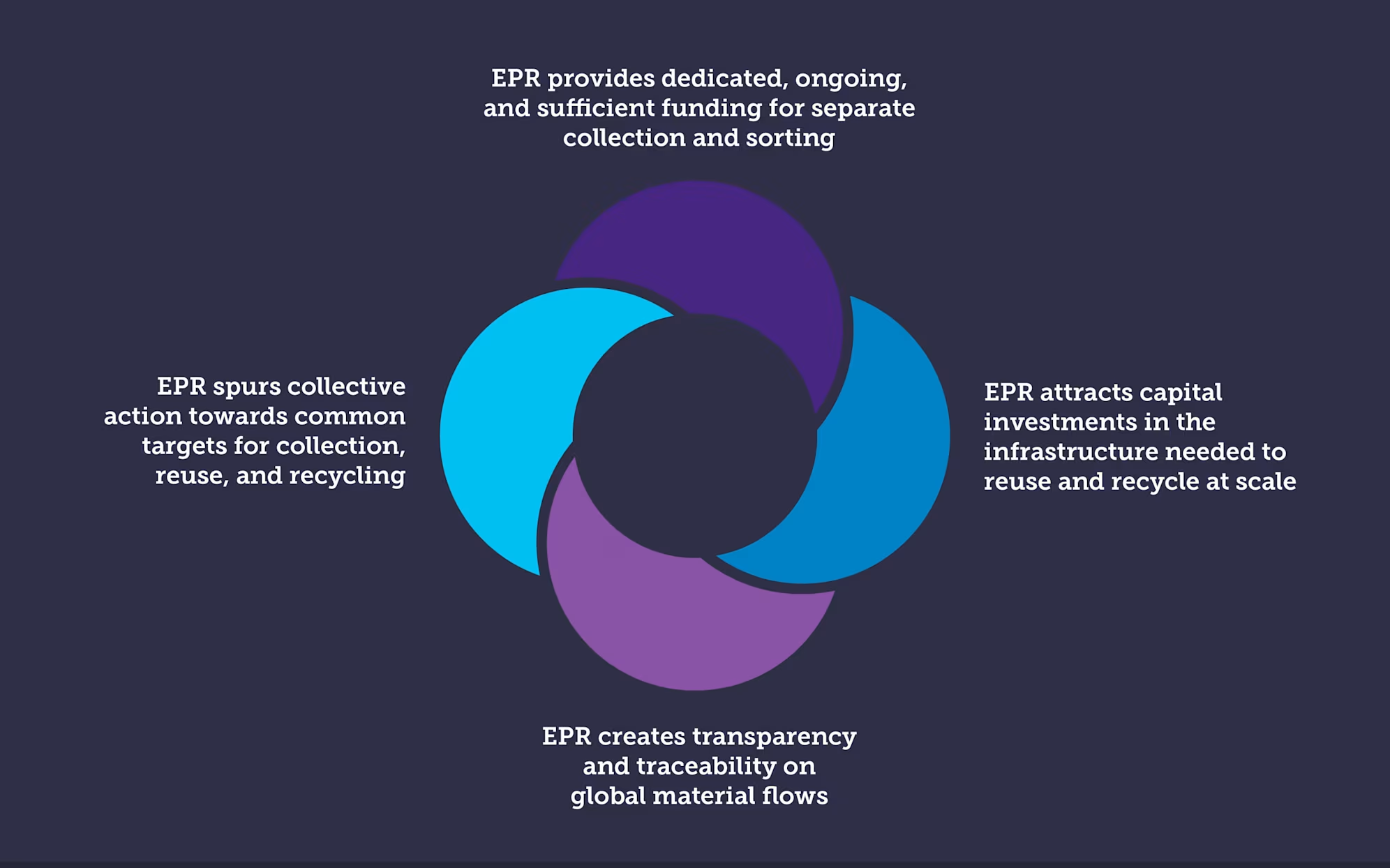

EPR policy places responsibility on producers for the collection, sorting and recirculation of their products when these are discarded by citizens. If designed well, EPR policy significantly improves the cost-revenue dynamics for separate collection, sorting, reuse, repair and recycling of discarded textiles. EPR also delivers transparency and traceability on global material flows, and it helps to attract capital investments in the infrastructure needed to reuse and recycle at scale.

Mandatory, Fee-Based EPR Offers Four Key Benefits

What is Wrong with the Current System?

Textile waste is a direct consequence of our linear economic system. Around the world, the vast majority of textiles (more than 80%) leak out of the system when they are discarded: they are incinerated, landfilled, or end up in the environment. Separate, dedicated textile collection systems are underdeveloped and do not capture all textiles placed on the market.

In our current textile system, most business models are linear: they are based on high volumes of new products, made from virgin resources, which are often used for a short time and then thrown away. Currently, products are not always designed to last and are often hard to recycle.

Separate collection is the only way to keep textiles from ending up in the waste stream or worse, the environment. But today, the economics of separate collection and sorting do not stack up. Collecting and managing discarded textiles happens at a cost (beyond textiles with high reuse value), and sorters around the world experience challenging profitability. This is a key barrier to achieving a circular economy for textiles.

The Business Case for Sorters in Europe, Kenya, and India

How Do We Make EPR Deliver Circular Economy Outcomes?

EPR policy is a starting point and needs to evolve to deliver circular economy outcomes. Today’s EPR policy leaves opportunities untapped by focusing on downstream activities, such as recycling. EPR has the potential to drive action upstream, by encouraging circular design, extending the use phase of textile products, and addressing pollution impacts, such as microfibre leakage.

To achieve a global circular economy for textiles, national EPR systems need to align around the same key objectives, while setting targets that are tailored to the national or regional context. In addition, the idea of extending EPR policy beyond national borders should be explored further, to manage textile waste where it ultimately ends up.

What Can Businesses Do to Accelerate Progress?

Policy alone cannot solve the problem of textile waste. Voluntary business action, including the establishment of voluntary EPR schemes, are key to accelerate progress. Coordinated and compounding industry action is needed to challenge the linear economic model at its core, and to capture the opportunity to reuse and recycle textile products and materials at scale. To accelerate progress, businesses can…

- Design products in line with circular economy principles

- Accelerate the adoption of circular business models through collaborative, multi-brand systems

- Invest in shared infrastructure that allows for the recirculation of materials after maximum use

To quote the study, please use the following reference: Ellen MacArthur Foundation, Pushing the boundaries of EPR policy for textiles (2024).

Content within community news is often paid for our sponsored by community members.